Four Fundamental Steps of a Continuous improvement Process

Today, I'm going to share with you what I've learnt about the principles of continuous improvement, which have nothing whatsoever to do with methods, tools or techniques.

Not that they aren't important. But to really have an impact, having these principles as the background context will be what makes the difference.

Since the start of my consulting career, I've tried every continuous improvement technique under the sun.

I started with Lean, Six Sigma, but was disappointed with the diminished localised impacts.

Then I moved onto Theory of Constraints… this methodology definitely has the ability to make large and very global impacts to a business, but it so counter-intuitive it's hard to get people to listen let alone give it a try.

Finally, I moved into change management, which is the bulk of the consulting and contracting work I do now.

Principle 1: Stop fixing and start improving

![]() The first of the principles of continuous improvement is that too much focus on process and their methodologies stifle innovation and creativity. Instead, stop focusing on methodologies and instead focus on improving.

The first of the principles of continuous improvement is that too much focus on process and their methodologies stifle innovation and creativity. Instead, stop focusing on methodologies and instead focus on improving.

Often the underlying context when organisations roll out process improvement methodologies is problem-solving and fixing what's broken.

Lean is not about applying a set of tools. Rather, it involves adopting a set of principles to how you run and improve your business. When organisations approach Lean as a set of 'tools' to be deployed, they often fail to achieve the results they are capable of. This is a result of a rigid and tactical adherence to a set of tools and frameworks, instead of adopting the basic principles of Lean.

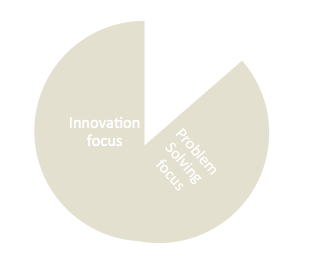

There is an overemphasis on problem-solving, usually at the expense of innovation. If people are constantly trying to fix things, then they are rarely working to improve things. This image bellow demonstrates the difference between the two.

In addition to bureaucracy, process methodologies can breed a pernicious focus on problem-solving. Six Sigma, Lean and others are, at their heart, problem-solving methods used to "fix", "solve" and "repair", as well as being used to put out fires.

In addition to bureaucracy, process methodologies can breed a pernicious focus on problem-solving. Six Sigma, Lean and others are, at their heart, problem-solving methods used to "fix", "solve" and "repair", as well as being used to put out fires.

In most cases, the businesses are trying to restore previously held performance. For example, an individual or department's performance has slipped, or in manufacturing environments perhaps equipment has failed.

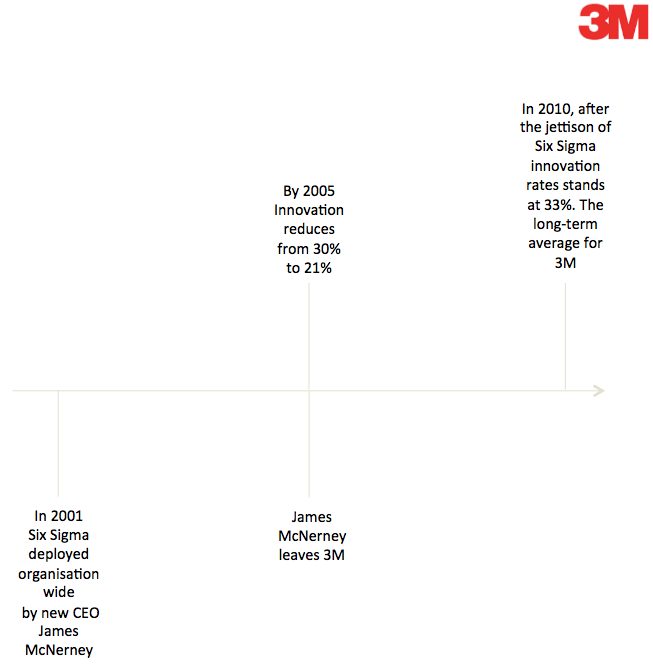

3M takes up Six Sigma and pays the price

Take 3M for example, long a leader and oft cited for its innovation, employed Six Sigma as a strategic enabler when the then new CEO James McNerney , from GE, came onboard in 2001. He cut costs, trained thousands of employees in the method and demanded rigorous process metrics on R&D .

During his tenure to 2005, they indeed cut costs and improved efficiencies, but at a cost. A key measure for 3M is the revenues made from products that didn't exist three years prior. Typically it sat at around 30%. During McNerny's time at the helm, it reduced to 21 percent.

Efficiencies were indeed made, having improved margins by some 17 percent, but at the detriment of innovative new products.

Problem-solving is not the opposite of innovation and it is not necessarily mutually exclusive. After McNerney's departure for Boeing in 2005, 3M still kept Six Sigma as a tool for improving their manufacturing efficiencies but left it out of the rest of the organisation where instead they instituted a significant innovation program once again.

They set up small, cross-functional teams who were moved away from their existing departments to network and collaborate on new projects across the organisation. Each new contact offered a new opportunity to redefine important attributes of future market demand and/or innovative approaches.

3M went on to create a safe environment allowing people to take risks and allowed the time required to develop novel, hopefully, revolutionary strategies, products and services that change the basis of competition in the markets applied, and in 2010 their percentage of sales from new products was back at 30% and growing.

Assess your organisation's focus

Consider your own organisation using this simple diagnostic. Imagine a pie chart, and divide it into the amount allocated to problem solving versus innovation.

Is it 90/10 to problem solving, or more like 65/35 to innovation?

Most organisations reward the problem-solving and penalise innovation since risk is inherent. Ask yourself if your organisation is close to a 50/50 ration in their focus on these two elements (the focus is usually 95/5 in favour of problem-solving).

Thoughts into action

![]()

![]()

Recognise that problem solving and improvement are two different disciplines

![]()

![]()

When there is a problem, look to improve the old standard not just restore it.

![]()

![]()

Constantly seek to raise the standard on each important performance measure

![]()

Exclusive Blog Post Bonus: Download a shareable PDF version of this post, PLUS get a free BONUS 7 part email course on Introduction to Leading Change.

Principle 2: The best practices are the ones you already have

![]() "We engage our colleagues globally to identify innovative ideas to exploit and develop."

"We engage our colleagues globally to identify innovative ideas to exploit and develop."

That's Walgreens Tim Theriault's, talking to Forbes contributor Peter High about how they approach change and innovation.

It's a popular notion that strategy is about a strong vision for the future and that what is getting in the way of reaching this strategy is poor implementation. It's common to cite the statistic that 70 percent of change initiatives fail, as if the chief executives have the ability to forecast the future. The idea that success will go to those who see it first.

![]()

![]()

In order to grow managers must be looking for new ideas and opportunities.

![]()

![]()

Ironically it's typical to look outside thinking that we must be doing something wrong.

![]()

![]()

It's the internal best practices, and the distinctive capabilities of the individuals that make up the firm applied to markets which cause results. Focus on the communication and coordination of the "architecture of relationships" that make up the firm.

Always looking externally for best practice?

Success goes to those change leaders who first look to the internal best practices, and distinctive capabilities and then marry them with outside technology, capital, assets and external best practices.

On the one hand, organisations must look outward to ensure they're providing the right products and services. But on the other hand, they must look to their internal best practices to ensure they're delivering those products and services in the most effective and efficient way possible. How to resolve this conundrum?

As Google demonstrates, the market goes to those who have distinctive capabilities, which can be applied to particular markets. Google started out with the expertise and notion that they were a search engine company. But later realised this capability could be then be applied in a different way. The "we want to know everything" notion, which sparked projects such as Google Earth, Google Book Search, and Google Labs, along with further improvements to their renowned search engine.

![]()

![]()

*Take Benetton, an Italian clothing retailer, which in 1987 hired a finance director from Citibank and announced that it would pursue the financial services markets. Benetton with distinctive capabilities in clothing and its distribution and retailing, not surprisingly, failed at this endeavour.

![]()

Strength in relationships

This, of course, is easier said than done. And herein is the art of change management. Sometimes skills and behaviours must reorient to newer markets and in new ways, just as Google was able to apply its search skills to that of maps and books.

Successful companies are rarely successful because of prescient insight and superior skills. Instead, they look at the skills and capabilities that make them successful now and apply them outwards to markets and clients.

This kind of insight leads to the kind of programs that Walgreen's has embarked on.

Theriault set up a three-stage program where they begin at ideation incubating ideas and marrying them to existing capabilities:

![]()

First, Walgreen's began with ideation incubating ideas and marrying them to existing capabilities

![]()

Second, they test these in the real world seeing if customers are responding. If they are they then develop them further.

![]()

Third, they implement where they aggressively leverage their existing capabilities to bring it to the market

To bring about change and reach strategic goals, first look at the skills, distinctive capabilities and the relationships that tie them together and apply them outwards.

The second of the principles of continuous improvement: Rather than slavishly borrow standards from elsewhere, define your own standards against your own goals.

Thoughts Into Action

![]()

![]()

Assess your employees for the support they perceive you supply for innovation

![]()

![]()

Provide incentives and rewards for managers who stimulate innovation from their staff.

![]()

![]()

Set up cross-functional teams to look for opportunities and deliver on ideas

Exclusive Blog Post Bonus: Download a shareable PDF version of this post, PLUS get a free BONUS 7 part email course on Introduction to Leading Change.

Principle 3: Changing behaviour is more important than changing processes

![]() When driving change at a pragmatic level, middle and frontline managers are often squeezed and their influence on the outcome is misunderstood. One significant cause is that senior leaders misinterpret people's value drivers.

When driving change at a pragmatic level, middle and frontline managers are often squeezed and their influence on the outcome is misunderstood. One significant cause is that senior leaders misinterpret people's value drivers.

![]()

Whether it's processes, technology or a restructure, we're still talking about "tools" that people use to get the work done.

![]()

![]()

Changing behaviour is more important that changing processes.

![]()

![]()

Understanding what gives us access to causes a change in people's behaviour can help us create whole new worlds of productivity.

Middle managers as engines of change

Social science researcher Dr Danah Zohar has looked at what drives senior leadership versus the frontline staff and middle managers. Zohar has shown that what managers and employees value the most in their work did not correlate at all to what drives senior leaders.

What the leader cares about (and typically bases at least 80 percent of his or her message to others on) does not tap into roughly 80 percent of the workforce's primary motivators for putting extra energy into the change program.

This same effect can also be seen in research by Capgemini Consulting and the IESE business school annual Global Innovation Leadership Study. Based on a survey of 260 innovation executives around the world, they concluded that "large organisations create so much distance between the executives and those that are tasked to innovate that a disconnect exists between them."

P&G reinvigorate their product innovation pipeline

Procter & Gamble, famous for its innovative culture, was not so innovative in the early 2000's.

At the time, just 15 percent of its innovations were meeting revenue and profit targets. Frustrated with the results, P&G set about an organisational change program to recast them as an innovator.

P&G pushed innovation responsibilities to the front line, embedding innovation and continuous improvement into everyday processes and procedures.

Within a year, building on 26 patents, it incorporated these additives into a new detergent, Tide with Acti-Lift—the first major redesign of Tide's liquid laundry detergent in a decade

So how much value do frontline and middle management deliver?

P&G's turnaround suggests that the value of middle managers is underestimated.

Wharton University researcher, Ethan Mollick, conducted a similar study. He asked IT project managers how much value middle managers drove, and the results were startling.

"After controlling for many factors, such as the genre of the game and the size of the project, I found that individual producers [managers] account for 22.3% of the variation in company revenue. Designers, by contrast, account for just 7.4% of the variation — a relatively marginal impact. For comparison, everything else that's part of the firm, whether it's senior managers or strategy or marketing, accounts for just 21.3% of the variation in firm performance."

Thoughts Into Action

While top leadership commitment is necessary, it is not sufficient. The direction may be set at the top, but behaviour is only changed with training, coaching and mentoring which needs to be reinforced and modelled daily.

Who else but a frontline manager can offer this high touch help?

Change leadership is a contact sport. This belies the principles of continuous improvement. If you want to create momentum around change, engage your middle and frontline managers for maximum impact

![]()

![]()

Review the playing field and its boundaries. Resources, budgets and constraints must be reviewed regularly to make sure they work

![]()

![]()

Employees won't necessarily want the accountability that comes with empowerment. You need to appeal to what's in it for them

![]()

![]()

The middle and frontline manager is the most important lever in organisational productivity. Ensure they're supporting empowerment and not undermining it.

Exclusive Blog Post Bonus: Download a shareable PDF version of this post, PLUS get a free BONUS 7 part email course on Introduction to Leading Change.

Principle 4: If you aren't failing, you aren't trying.

![]()

Ultimately, small-scale experimentation pays off in big ways, but experiments necessarily fail.

![]()

Small-scale experimentation pays off in big ways, but to experiment is to risk failure.

![]()

![]()

The Right Idea is priceless and worth the inevitable failures.

![]()

![]()

The value in learning from success and failure.

Many businesses don't grow unless they innovate, and innovation comes from developing and implementing new ideas. However, innovation usually carries a risk of some kind. For example, fundamental assumptions could be wrong, new products may not work sufficiently well, or customers may not accept your ideas.

This is why it's so useful to run business experiments and underlies the principles of continuous improvement. You can use them to help you understand how your idea might perform on a larger scale. You can also learn from your failures and mistakes, and refine your ideas to make them better.

Business experiments can involve anything from basic tests (for example, changing the welcome message on your website or testing a new process for dealing with telephone enquiries) to more complex projects (for example, testing a new product or service with a small number of customers).

The Right Idea is Priceless

Ideas are cheap and implementing them is expensive, but implementing the right idea is priceless. The question is, how do we find those gems? Experimenting – and through experimenting, learning. Consider IBM and its approach to experimentation.

IBM sponsors crowdsourcing sessions known as InnovationJam.

![]()

These 72 hour long events involve 150,000 employees, family members, business partners, and clients.

Through these collaborative efforts, people with a variety of backgrounds can engage in brainstorming exercises that are meant to bring about the next generation of growth for the company.

![]()

In 2006, IBM poured $100 million into 10 experiments that were to be conducted on a small scale. Emerging areas of interest included water, energy, transportation systems, and health care.

![]()

Master inventor Colin Harrison, who had participated in these jam sessions, joined a corporate strategy team in New York that endeavoured to simulate a venture environment. Ideas were organised and presented directly to the company's CEO.

In reflecting on the team's beginnings, Harrison noted that they started very small. Even though he worked with hundreds of people, no one reported to him.

Because he had access to so many people with so many different skillsets, he was able to take advantage of resources outside of his realm of expertise.

![]()

InnovationJam isn't the only way IBM has capitalised on innovation. The company has also spearheaded a project known as EBO's, or emerging business opportunities. Each EBO leader is given the funds and resources to test out the project on a small scale and thus prove its value. If these initial pilots are successful, teams are then given the opportunity to take experimentation to the next level by involving a few customers.

At each milestone, IBM makes decisions about whether or not to keep supporting the project. Success isn't always measured by how much money the experiment has made – the difference between $1 million and $50 million may not even matter. What's more important is whether or not customers and clients think the project is valuable. If customers and clients want to see more, there's a good chance the final idea will be profitable.

Assess your organisations' willingness to take risks

The organisation's history, culture and reward systems determine acceptance to change. Having the "freedom to fail" and acceptance of prudent risk must be culturally acceptable.

Reactions to proposed changes are determined by an organisations culture.

The Value in Learning from Success and Failure

Ducati may not seem like the best example of the business environment. After all, it's a far cry from the world of IBM. But when the company entered the Grand Prix motorcycle racing circuit for the first time in 2003, their approach ended up saying a lot about the value of testing.

![]()

As it was their first year, they didn't expect much. They approached it more as an opportunity to learn. So they set out to test features that would one day build a better bike by fitting bikes with sensors that captured data on nearly 30 different performance parameters. The data was discussed with riders, who could then adjust their behaviour based on feedback.

As it was their first year, they didn't expect much. They approached it more as an opportunity to learn. So they set out to test features that would one day build a better bike by fitting bikes with sensors that captured data on nearly 30 different performance parameters. The data was discussed with riders, who could then adjust their behaviour based on feedback.

Their bike ended up being the fastest in the field and they finished near the top in nine different races – a completely surprising result. The next year they grew so excited that they changed approximately 60% of the bike's features, thinking they could get a title. They still did well, but they didn't get the first place prize they wanted. Back to the drawing board.

Their bike ended up being the fastest in the field and they finished near the top in nine different races – a completely surprising result. The next year they grew so excited that they changed approximately 60% of the bike's features, thinking they could get a title. They still did well, but they didn't get the first place prize they wanted. Back to the drawing board.

![]()

Motivated by what they viewed as a failure, the team re-examined their approach to design and allowed for an additional testing time before the season began. Their thorough testing paid off, and by 2007 Ducati won that world title they had long desired.

Motivated by what they viewed as a failure, the team re-examined their approach to design and allowed for an additional testing time before the season began. Their thorough testing paid off, and by 2007 Ducati won that world title they had long desired.

Ducati's story points to the importance of experimentation and learning regardless of whether you have previously experienced success or failure. Testing new ideas comprehensively and piloting them in small, minimal risk environments may test your patience, but it will ensure value."

![]()

Thoughts Into Action

Reward behaviours and not just victories. One organisation, Tata Motors, an Indian car company implemented a reward for the best idea that didn't work. Now that's recognising forward thinking behaviour.

![]()

![]()

Reward behaviour not just victories. Reward people who attempt new approaches regardless of outcomes.

![]()

![]()

There is a difference between gambling and prudent risk. Encourage the latter.

![]()

![]()

Provide process and support so that improvement and innovation is not seen as risky and ambiguous.

![]()

Exclusive Blog Post Bonus: Download a shareable PDF version of this post, PLUS get a free BONUS 7 part email course on Introduction to Leading Change.

Source: https://daniellock.com/4-principles-of-continuous-improvement/

0 Response to "Four Fundamental Steps of a Continuous improvement Process"

Post a Comment